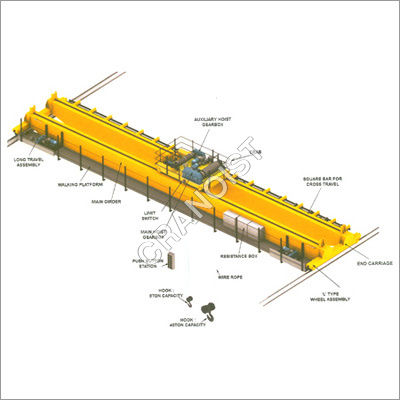

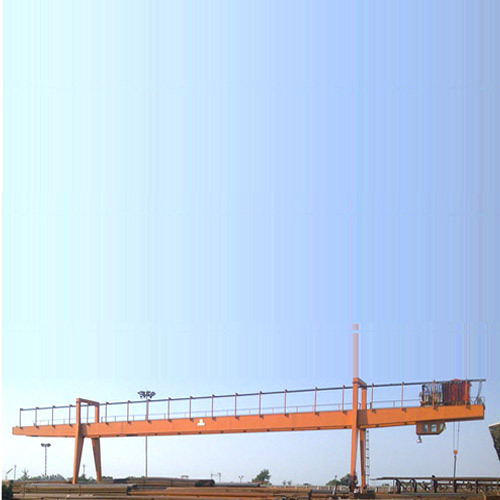

Double Girder Type Goliath Cranes

Product Details:

Product Description

We are renowned manufacturer, supplier and exporter of finely finished Double Girder Type Goliath Cranes. As demanded by clients, these cranes are precisely-engineered using high grade raw materials that are sourced from authentic vendors of the market. Post-production, these cranes are duly checked on various set parameters to ensure superior performance. Clients can avail these cranes in various sizes and specifications as per their needs. Double Girder Type Goliath Cranes are delivered to clients within the promised time frame.

Key Features:

-

Equipped with double girders that provide easy handling of materials

-

Anti-corrosive nature and high load bearing capacity

-

Specially designed for lifting of heavy duty goods

-

Fitted with superior quality hydraulic components

-

Smooth functioning for fast execution of work

-

Long service life with trouble free performance

Specifications:

| Capacity | Up to 100 ton |

| Span | Up to 30 mtrs |

| Long travel speed | Up to 20 mtrs / min |

| Cross travel speed | Up to 15 mtrs /mi |

Applications:

- Steel Yards

- Granite and Open Yard

- Container Deputes

- Storage places

- Ports / Ship Yards

- Construction and Engineering Industries

- Cement Pipe Industries

Optional Features:

- Micro speed arrangement through variable frequency drives / frequency inverters

- Cable festooned system / shrouded bus bar system

- Warning horn and Bridge lights

- Cabin operated through master controller

Other Details:

Design:

CRANOIST electric overhead traveling cranes are designed & manufactured accordance with IS 807, IS 3177, code of practice for design, manufacturing, erection, testing of structural part of the crane and IS 3177 code of practice for design of overhead traveling crane. In the design of components adequate factors of safety as per relevant code is allowed impact, fatigue, wear & stress concentration factors are taken whenever applicable. All drives are designed to give sound & efficient performance.

Steel Construction:

Structural steel are used in the manufacturing of crane confirming to IS 2062 or equivalent.

Bridge Girder:

The bridge girder is fabricated from RSJ / Box type construction in the manufacturing. The maximum deflection of the bridge girder is limited to span / 1000 of the live loads. Bridge girder is designed to sustain stress creating due to vertical & cateral forces with impact.

End Carriages / End Trucks:

End carriages are fabricated from rolled steel section / plate with adequate diaphragms & stiffeners to give a rigid construction. The girders with gusset plates are set on the end carriages joined with bolt in rimmed holes, rubber buffers are provided on both the side of end carriages for abhorring the jerks. Twin drive arrangements will be provided for L.T. motions, central drive arrangement also available on request.

Hoisting Machinery:

The hoisting machinery / crab is designed with IS 3938 in modular construction which simplifies repair & maintenance consists of a CRANOIST heavy duty industries type std. wire rope hoist.

Controls:

- The crane is controlled from pendent push button station is suspended from the one end of bridge at a suitable height from the floor level with stepped down voltage of 110v, 24v.

- Dust proof powder coated sheet - metal housing consists of contractors overload relays fuses, transformers etc.

- Emergency stop button in all cranes to shutting off the power to the main contractors.

Motors & Brakes:

- The motors used are specially crane duty suitable for frequency starting, reversing and braking in accordance with IS 225.

- All trolley and drive motors have suitable AC/DC/brakes as std. equipments with smooth running properties.

Other Products in 'Girder Overhead Crane' category

|

|

|

|

CRANOIST MATERIAL HANDLING EQUIPMENT PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |